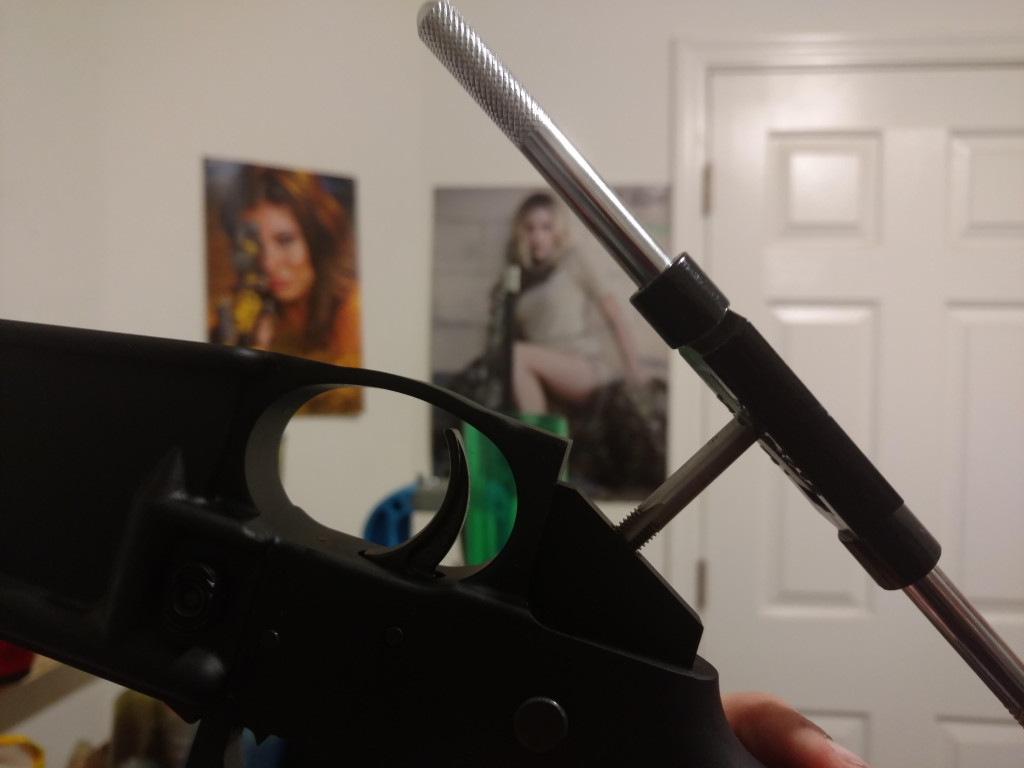

A few weeks back I bought a few Anderson lowers from AIM Surplus for $40. The anodizing and machining look very nice. However the grip screw hole wasn’t threaded nearly far enough, even for the shortest grip screw I had. Fastest solution was to tap that hole with a 1/4-28 tap. Okay, so I don’t have the most expensive tap and die set in the world, but for my low volume needs, it works fine.

I also noticed that the bolt catch detent hole wasn’t deep enough prior to anodize, but they had apparently caught that and drilled it deeper, through the anodizing.

I assembled the lower with PSA PTAC lower parts (purchased from PSA as part of rifle kits) and don’t have anything bad to say about them so far. The trigger pull is actually quite crisp and none of the other components seemed to vary from other LPKs I’ve used in the past in terms of quality or appearance.

Having to tap the grip screw hole was annoying, but a diversion of only a few minutes and I’d still say these $40 lowers are well worth the price.

I’ve taken a few of the uppers apart and noticed disappointing things like barrel nuts torqued to over 100 ft-lbs (they should be over 30 but I prefer less than 80) without the use of anti-seize, front sight bases that are slightly canted, taper pin holes drilled haphazardly, etc. But nothing that has affected function yet – zero malfunctions so far with all seven uppers -not a very high round count, but a good mix of brass and steel cased stuff.

This is definitely the time to buy if you’re looking to build an AR.

So what I’m hearing is a budget pets bucket PSA put together by Bubba in Columbia is better than a “specialty” AR made by Battle Rifle Company?

So far that’s something I’d agree with.

I haven’t had any issues with anything Anderson…yet, but I have had a few issues with PSA PTAC parts. The premium PSA stuff works great, but I’ve had a PTAC FCG that would not reset after each trigger pull, a safety selector that I had to fix with a Dremel and a few takedown/pivot pins that were very loose and sloppy.

Glad to hear the lowers and parts kits are legit. Nice photo composition.

Have used several Anderson lowers from Aim Surplus at $40 a pop. High quality and zero issues for me. Mated to a PSA freedom kit and is a very high quality rifle. As good as rifles at 1.5-2 times the price… And I was the engineer at a company selling rifles for $2000 a pop…. Definitely the time to build a rifle if you can shell out $500-700. Anderson + PSA.

Great Article Andrew.

So did you stage that first picture with the girls in the background?

Anderson has been fairly good quality wise. The grip screw not being fully threaded might be because of 50 cent trigger jobs but Anderson should thread them deeper.

PSA has very nice stuff for the most part be I have to disagree about how cheap they are now compared to the past. An example of this is that the current daily deal is for a PSA 16″ CHF Mid-length Rifle Kit – # 8978 for only $600. Seems nice for a FN CHF chrome mid length gas barrel with standard furniture. Problem is that this kit in the past was only $600 sale price at the worst post Sandy Hook market time and most of the time priced at $500 on sale. And half the reviewers post about buying it for $500. And this is not the premium classic kit that includes a proper mil spec 7075 lower receiver extension.

Andrew, if you don’t mind me asking, what’s the general ballpark of your serial number? I just bought one and am curious if mine’s close to yours. Mine is 151648XX

I’m putting together a build soon, so I guess I’ll find out once I start. Cheers!

152351XX

I don’t know if they’ve made THAT many. Different numbers at each point might mean a different year, or different run – who knows.

I’m a fastener engineer, I develop torque strategies for all of the U.S. manufactures as well as many of the Japanese, Korean and Chinese.

You can not measure installed torque by measuring the torque required to break that barrel nut loose. You can’t extract the torque tension correlation or determine initial K factor (friction in the threads) by using the off torque characteristic.

You have a exemplary evidence driven blog, I’d be more than happy to expounded on the technical specifics if you’d like so you can update your post.

Anderson says most of their lowers require a 3/4″ grip screw. Is this a normal length?

I have several of the Anderson lowers I picked up and built out @ a year ago. Zero issues with the rifle lowers, magpul and B5 grip screws threaded in just fine, but the holes are definitely not threaded all the way. When I saw that I tried an old screw I had laying around from who knows what, but the longer milspec ones, and it wouldn’t snug up. Definitely would have to be tapped to be compatible.

One was a pistol lower (waiting on stamps) though, and it doesn’t always drop mags cleanly. Battlemags are good, Pmags are snug but drop with a shake, milspec metal hangs up. It is improving though with use, I’m not mad about it. For 99% of applications they are at least as good as many and better than a lot, for an unbeatable price.

My only PTAC experience is a 80 dollar BCG I used to build a rifle for my sister that barely gets shot, but it’s been flawless through both my initial testing and her intermittent current use. Its not pretty, definitely some rough machining, but it’s perfectly functional and, like the Anderson, a great value.